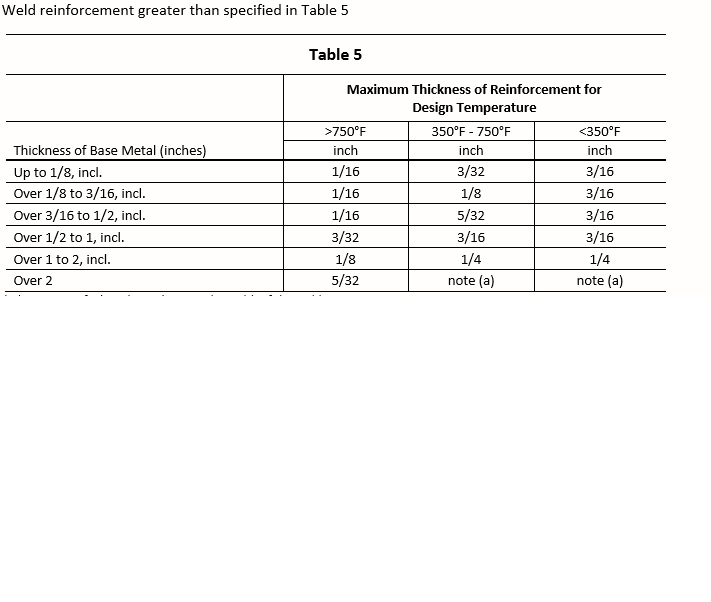

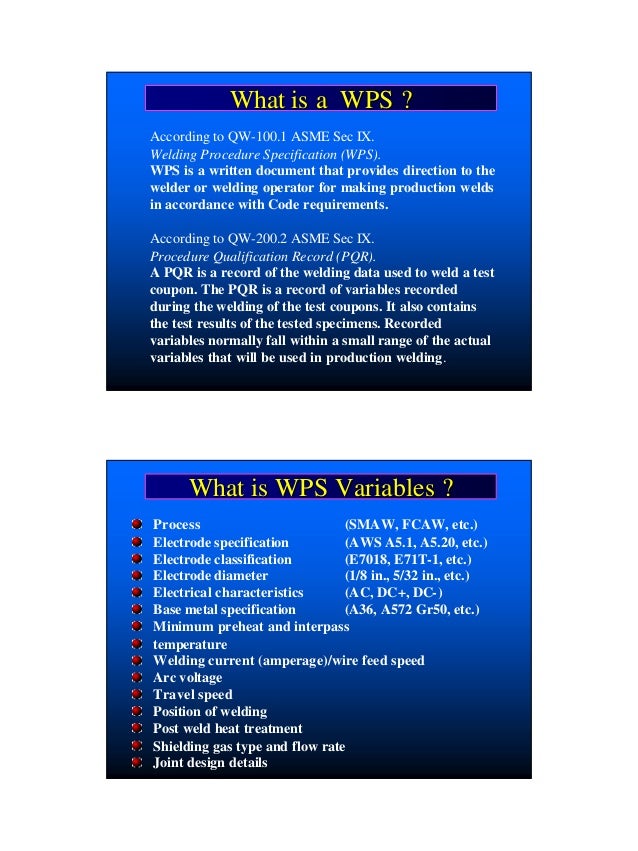

Article i covers the scope ofasme section ix the purpose and use of the wps pqrand wpq responsibility test positions types and purposes of tests andexaminations test procedures acceptance criteria visual examination andradiographic examination.

Asme section ix welder qualification range.

Asme sec ix welding procedure and performance qualification.

Asme section ix welding qualifications is a guide to the requirements of the asme boiler and pressure vessel code section ix welding and brazing qualifications.

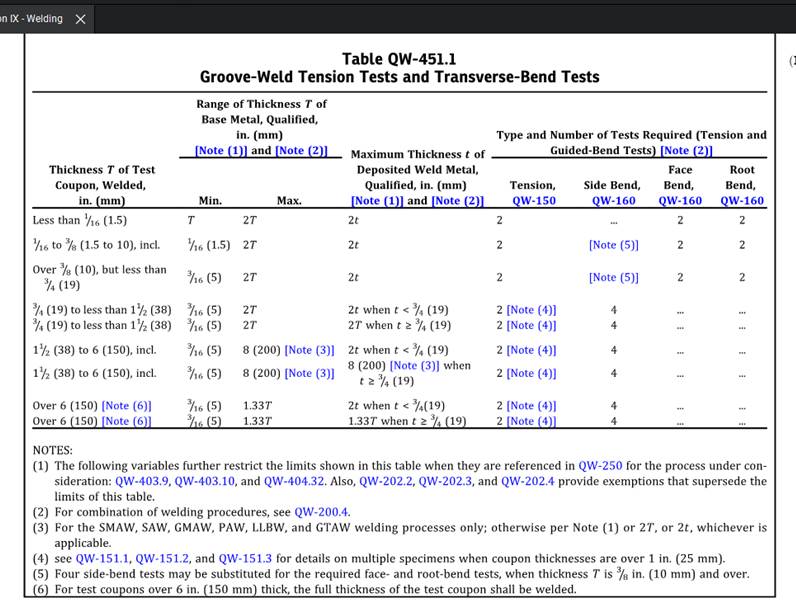

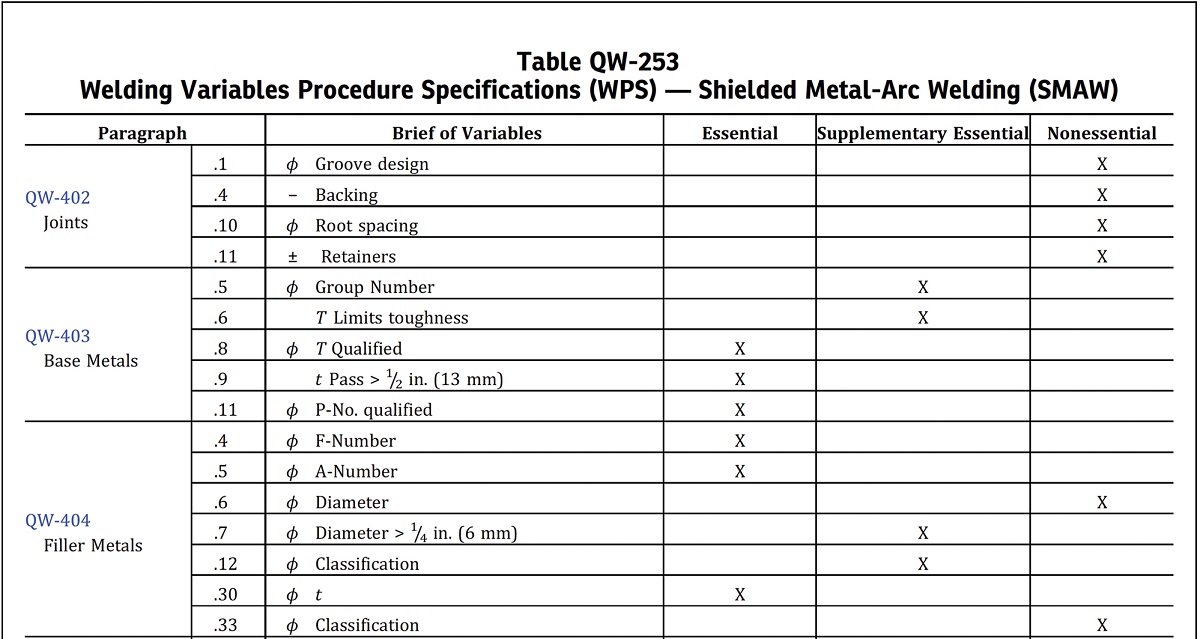

A simplified version of that table is given below.

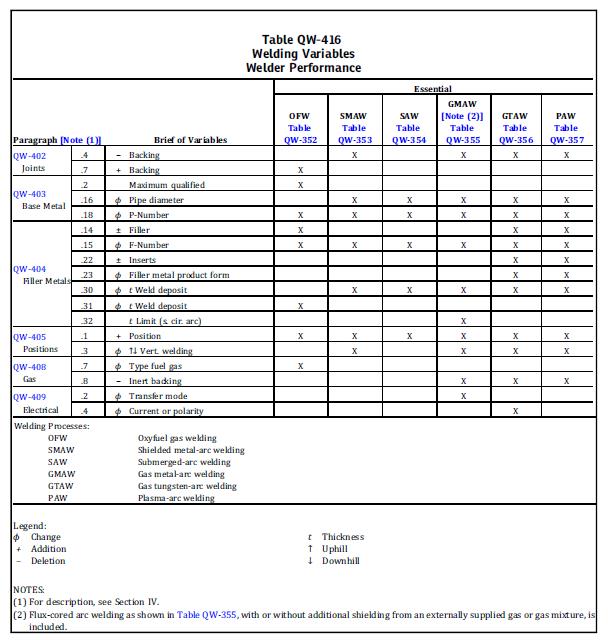

Section ix considers skill as important factor for welder qualification and the variables have been decided based on this consideration.

For example if a welder qualifies with a 10 mm thickness plate then he can weld upto a maximum of 20 mm thickness.

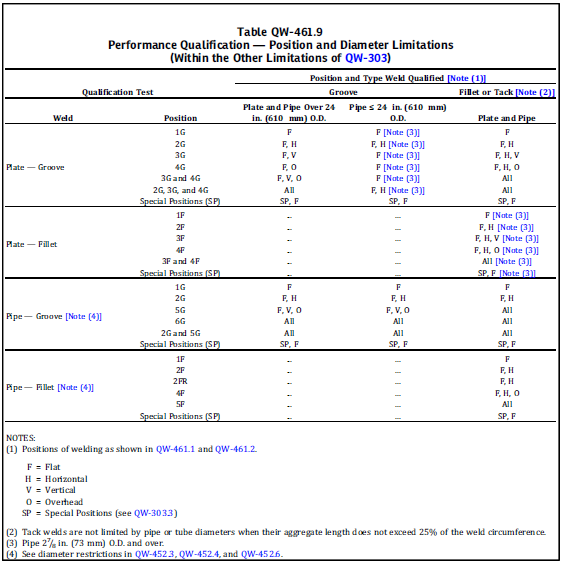

Outside diameter of test coupon.

Asme bpvc section ix has provided guidelines for the thickness range up to which a welder can weld.

4 3 2 and 1 with backing.

4 electrode your welder can weld only f no.

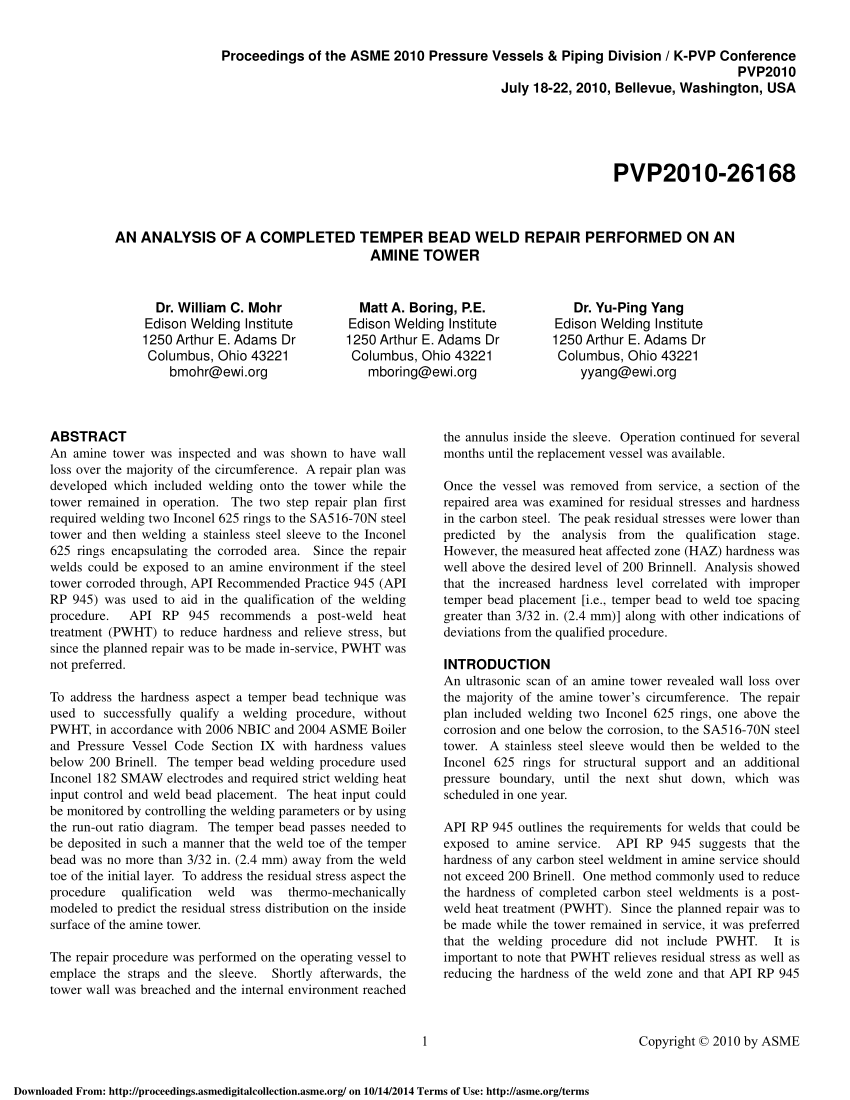

Two very widely used welding codes are aws d1 1 and asme bpvc section ix.

The preface of section ix contains an informative historical perspective on the development of the current code rules.

The qualifying ranges for pipe groove welds qw 403 16 qw 452 3 are.

Look at it this way if you qualify a welder on p no.

Performance qualification welder welding operator for performance qualification testing pipe diameter is an essential variable for the arc welding processes that are listed.

Section ix of the asme b pv code sets forth the qualification requirements for welders brazers and welding and brazing operators in addition to the procedures they follow in fabricating vessels components and piping to meet the b pv code and also the asme b31 code for pressure piping.

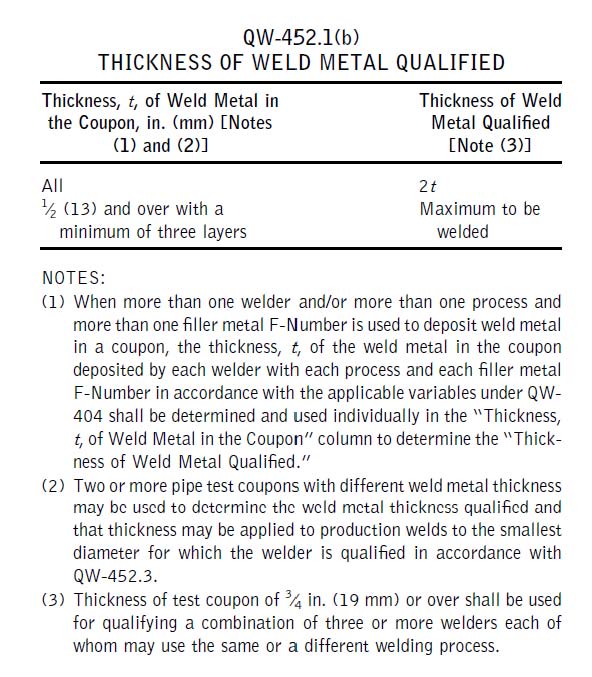

Thickness range for performance qualification welder qualification test.

It determines the performance qualification thickness limits i e.

1 with e7018 f no.

Upto what thickness the welder can weld.